Home > Our Products > Armor & Protection Steel Plates

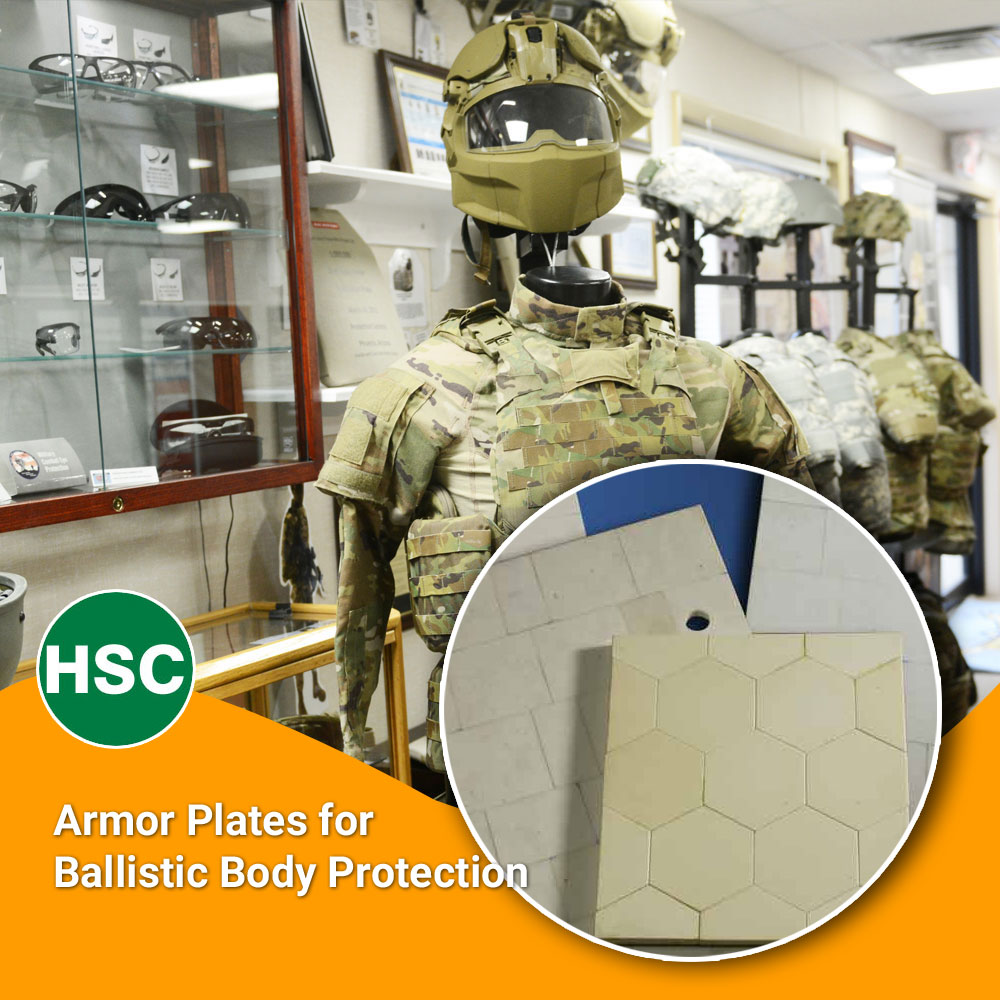

Built for Impact. Engineered for Survival.

In an age where threats come from both conflict zones and criminal activity, armor & protection steel plates are the silent shields behind secure missions, VIP convoys, border bunkers, and bullet-resistant checkpoints. These plates aren’t just made of hardened metal—they’re forged for life-saving performance.

Whether you’re a military supplier, vehicle armor fabricator, ballistic gear manufacturer, or infrastructure defense contractor, you need protection that’s field-tested, spec-compliant, and impact-certified. That’s where our range of armor-grade steel plates delivers unmatched reliability—from MIL-DTL-46100 to EN 1522 FB6 and STANAG 4569 standards.

Armor steel plate refers to a high-hardness, high-tensile steel sheet specifically developed to withstand ballistic impact, explosive blasts, and projectile penetration. Unlike ordinary structural steel, armor plates have enhanced Brinell hardness (BHN), superior fracture toughness, and energy absorption properties.

From urban combat zones to riot-prone civilian areas, armor & protection steel plates play a critical role in safeguarding lives, assets, and infrastructure. Below are the most common real-world applications across industries and institutions:

Integrated into steel doors, booths, counters, and teller windows in:

Armor plates are layered in blast-resistant structures for:

wear plates protect your machinery, bottom-line, and team.

Armor steel isn’t one-size-fits-all. Based on mission type, threat level, region-specific compliance, and user profile (military, VIP, civilian), different armor plate grades are engineered for maximum protection, performance, and cost-efficiency.

Here’s a breakdown of the most widely used types and grades:

| Grade / Code | Application | Standard / Use Case |

| MIL-DTL-12560 | Combat tanks, APCs, bunkers | US military-grade rolled homogeneous armor (RHA) |

| MIL-DTL-46100 | High-threat zones, vehicle upgrades | High-hardness armor for advanced ballistic defense |

| EN 1522 / FB6 / FB7 | European civilian/military bulletproofing | Used in security doors, VIP vehicles |

| STANAG 4569 Level I–IV | NATO-compliant armor for military & police use | Armored vehicles, blast protection |

| NIJ Level III & IV | Personal body armor (hard plates) | Standard for bulletproof vests & riot gear |

| Swebor 400 / 500 | Lightweight military/civilian armor | Swedish standard armor plate |

| Quardian 500 / PRO500 | Armored vehicles and riot-control barriers | High-performance European armor grade |

based on your blueprint or end-use requirement. Let us know your use case and we’ll suggest the ideal grade

| Parameter | Typical Range / Value |

| Hardness (BHN) | 480 – 600 BHN (MIL-46100, Quardian 500, HIND ARMOR 500) |

| Yield Strength | 1200 – 1500 MPa |

| Tensile Strength | 1400 – 2000 MPa |

| Elongation | 8% – 14% (Depending on grade & thickness) |

| Impact Resistance (Charpy V) | 20–30J @ -40°C or -20°C (grade dependent) |

| Weldability | Limited (requires preheat & special filler if any) |

| Ballistic Resistance | NIJ III, IV / MIL 12560 / 46100 / STANAG levels |

| Bend Radius | 4x to 6x plate thickness for cold bending |

| Plate Thickness Range | 3 mm – 120 mm |

| Available Sizes | 1250 x 2500 mm, 1500 x 3000 mm, custom on request |

When it comes to ballistic and blast protection, certification is not optional — it’s the minimum bar. That’s why each armor & protection steel plate we supply adheres to globally accepted military and industrial norms.

Here’s an overview of the standards and certifications you can expect:

| Standard Code | Standard Name | Application |

| MIL-DTL-12560H | U.S. Department of Defense Standard | Armor for combat vehicles, tanks, and shelters |

| MIL-DTL-46100E | High-Hardness Armor Steel Specification | Lightweight armor for tactical vehicles |

| STANAG 4569 | NATO Ballistic & Blast Standard | Protection levels for crew & equipment |

| NIJ 0101.06/07 | National Institute of Justice Body Armor Standard | Personal body armor, plates for bulletproof vests |

| EN 1522 / FB6 / FB7 | European Ballistic Standard | Civil defense (banks, checkpoints, doors, etc.) |

| Standard | Region / Body | Relevance |

| ASTM A514 / A673 | American (ASTM) | Structural integrity, weldability |

| IS 2062 / IS 276 | Indian (BIS) | Manganese and carbon alloy conformity |

| EN 10025 / EN 1522 | European Standards | Plate flatness, hardness verification |

| ISO 9001:2015 | International Quality | Factory-level quality assurance system |

If your project requires end-use approvals like STANAG certification, custom third-party testing, or mill attestation — we provide all documentation including:

When mission-critical protection is non-negotiable, global buyers trust Indian-manufactured armor plates for one key reason: affordability without compromising on standards.

At Hindustan Steel Corporation, we are a preferred armor & ballistic steel plate exporter from India, supplying to buyers across defense, security, infrastructure, and OEM industries in 25+ countries.

| 🌎 Region | 🚢 Major Export Destinations |

| Middle East | UAE 🇦🇪, Saudi Arabia 🇸🇦, Oman 🇴🇲, Qatar 🇶🇦, Iraq 🇮🇶, Jordan 🇯🇴 |

| Africa | South Africa 🇿🇦, Kenya 🇰🇪, Nigeria 🇳🇬, Egypt 🇪🇬, Ghana 🇬🇭 |

| Asia Pacific | Vietnam 🇻🇳, Indonesia 🇮🇩, Philippines 🇵🇭, Malaysia 🇲🇾, Thailand 🇹🇭 |

| Europe & UK | Germany 🇩🇪, France 🇫🇷, Netherlands 🇳🇱, United Kingdom 🇬🇧 |

| South America | Brazil 🇧🇷, Chile 🇨🇱, Argentina 🇦🇷 |

If your tender or organization requires:

Whether you’re a government contractor in Delhi, a security OEM in Pune, or a defense integrator in Hyderabad — we supply armor and ballistic steel plates PAN India with reliable turnaround, quality assurance, and custom support.

Multiple thicknesses of armor-grade steel in our Navi Mumbai warehouse

Send drawings / dimensions Get CNC cut plates ready for assembly

Pan-India supply chain via road, rail, and air cargo

GST-compliant invoicing & e-way bill

Third-party testing (ballistic lab reports)

Assistance in government tender paperwork

When every second matters and lives are on the line, HIND ARMOR™ Plates deliver uncompromising protection, certified reliability, and made-in-India excellence. Here’s why India’s defense units, OEMs, security agencies, and infrastructure planners trust our ballistic-grade steel:

Our plates are designed keeping in mind real-world Indian conditions — from high-temperature deserts to high-altitude cold regions. Whether for military vehicles, bulletproof cabins, or blast-resistant infrastructure, our grades handle it all.

We offer full compliance with:

All HIND ARMOR™ plates are tested for V50 velocity, backface signature, and multi-hit resistance.

No more delays in processing. Our ballistic steel:

We stock armor steel in:

Custom sheets, ready-to-ship panels, and one-time large volume projects — we’re equipped for all

We’ve supplied to:

Documentation, certifications, and paperwork support available as per GeM, eProcurement, or DGS&D norms.

Our team assists with:

Fast dispatch, tracking, and third-party inspection if needed

Whether you’re an OEM, defense contractor, or security infrastructure planner, sourcing ballistic steel isn’t just about price — it’s about lives, liability, and long-term performance. Here are key tips (and pitfalls to avoid) when procuring armor plates:

AR500 ≠ MIL-46100 or EN 1522. Abrasion-resistant plates are not tested for bullets.

“Bulletproof plate” is vague. Always specify standard + level (e.g., NIJ IV) to avoid mismatches.

If the seller can’t provide ballistic reports or fabrication advice — walk away

High-hardness plates need preheat and post-weld heat treatment. Ask for welding guidelines.

+91-22-66159018

+91-9820944724

sales@hindustansteel.com hindustansteel1@gmail.com

390/392, Ground Floor, Shankar Mansion, S.V.P. Road, Mumbai – 400004, India

We recommend offering the following resources in downloadable PDF format (optional gated form for lead gen):

Let me know if you’d like these documents drafted or designed in the next phase.

From urban combat zones to riot-prone civilian areas, armor & protection steel plates play a critical role in safeguarding lives, assets, and infrastructure.

Armor steel isn’t one-size-fits-all. Based on mission type, threat level, region-specific compliance, and user profile (military, VIP, civilian), different armor plate grades are engineered for maximum protection, performance, and cost-efficiency.

Armor steel isn’t one-size-fits-all. Based on mission type, threat level, region-specific compliance, and user profile (military, VIP, civilian), different armor plate grades are engineered for maximum protection, performance, and cost-efficiency.

Explore All →

Curious about how manganese steel behaves, whether it rusts, or how it compares with AR steel?

When mission-critical protection is non-negotiable, global buyers trust Indian-manufactured armor plates for one key reason: affordability without compromising on standards.

Fabrication advice and performance comparison

When it comes to ballistic and blast protection, certification is not optional — it’s the minimum bar.

Whether you’re an OEM, defense contractor, or security infrastructure planner, sourcing ballistic steel isn’t just about price — it’s about lives, liability, and long-term performance.

+91-22-66159018

+91-9820944724

sales@hindustansteel.com hindustansteel1@gmail.com

WhatsApp us