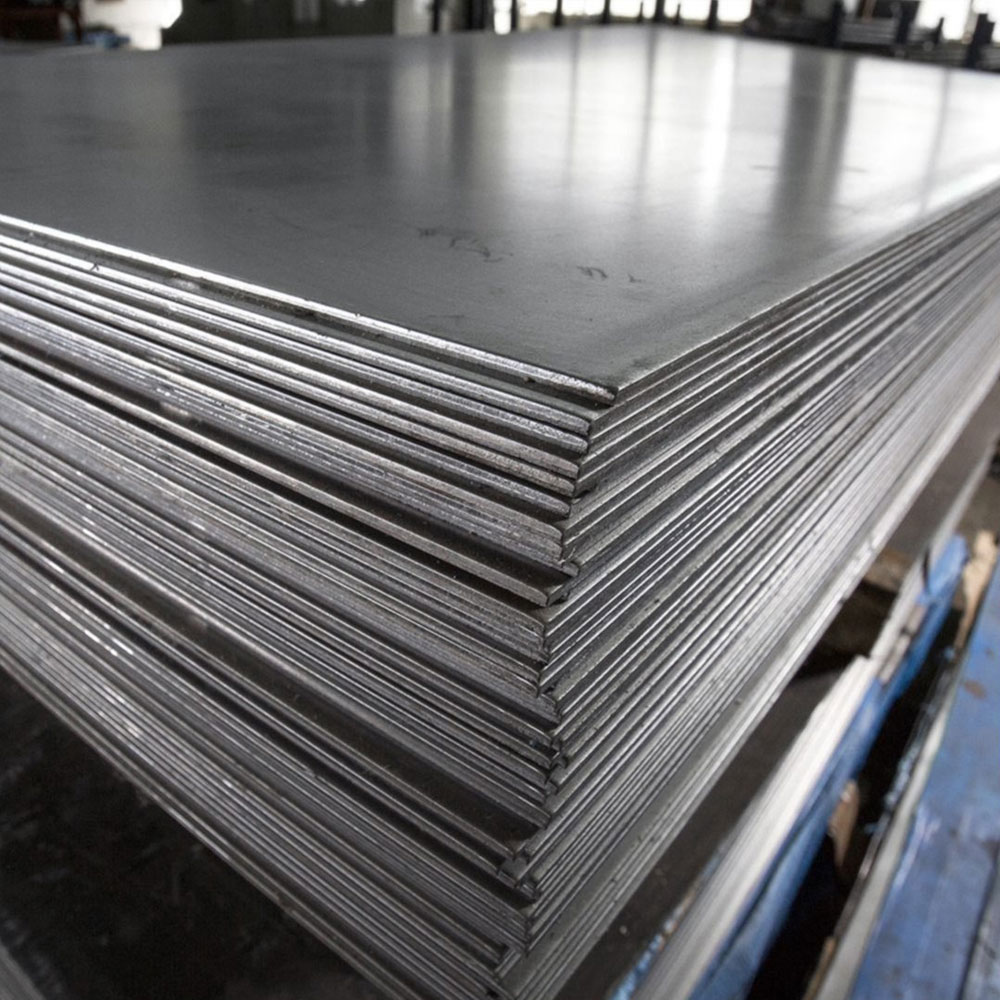

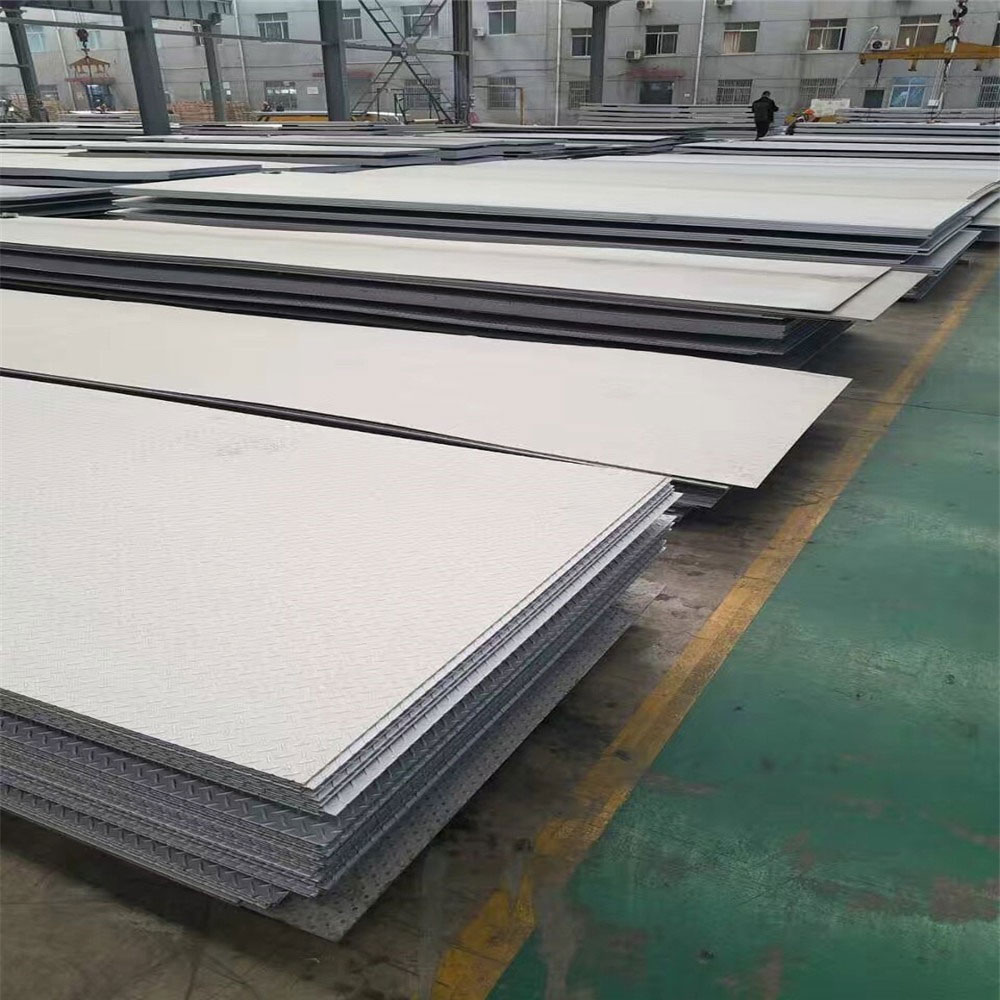

Over the years, HSC has grown to become a trusted name for engineering-grade steel plates under our in-house HIND Brand

At Hindustan Steel Corporation, we combine in-house manufacturing strength with strategic global sourcing to deliver high-performance steel plates engineered for real-world industrial demands. Whether you’re sourcing wear-resistant plates for mining, ballistic steel for defense, or boiler plates for pressure vessels, we provide certified, cut-to-size, and application-matched materials — fast.

We don’t just stock wear plates — we manufacture, customize, and export steel solutions that meet

the demands of mining, defense, construction, agriculture, and OEM fabrication.

Built to endure extreme abrasion

Shock-absorbing strength for impact-heavy environments

Ballistic-grade steel for military and security systems

From abrasion-resistant wear plates to boiler-grade pressure vessel steel, Hindustan Steel Corporation offers a comprehensive range of plates to meet the most demanding industrial needs. All materials are tested, certified, and cut-to-size as per your requirements.

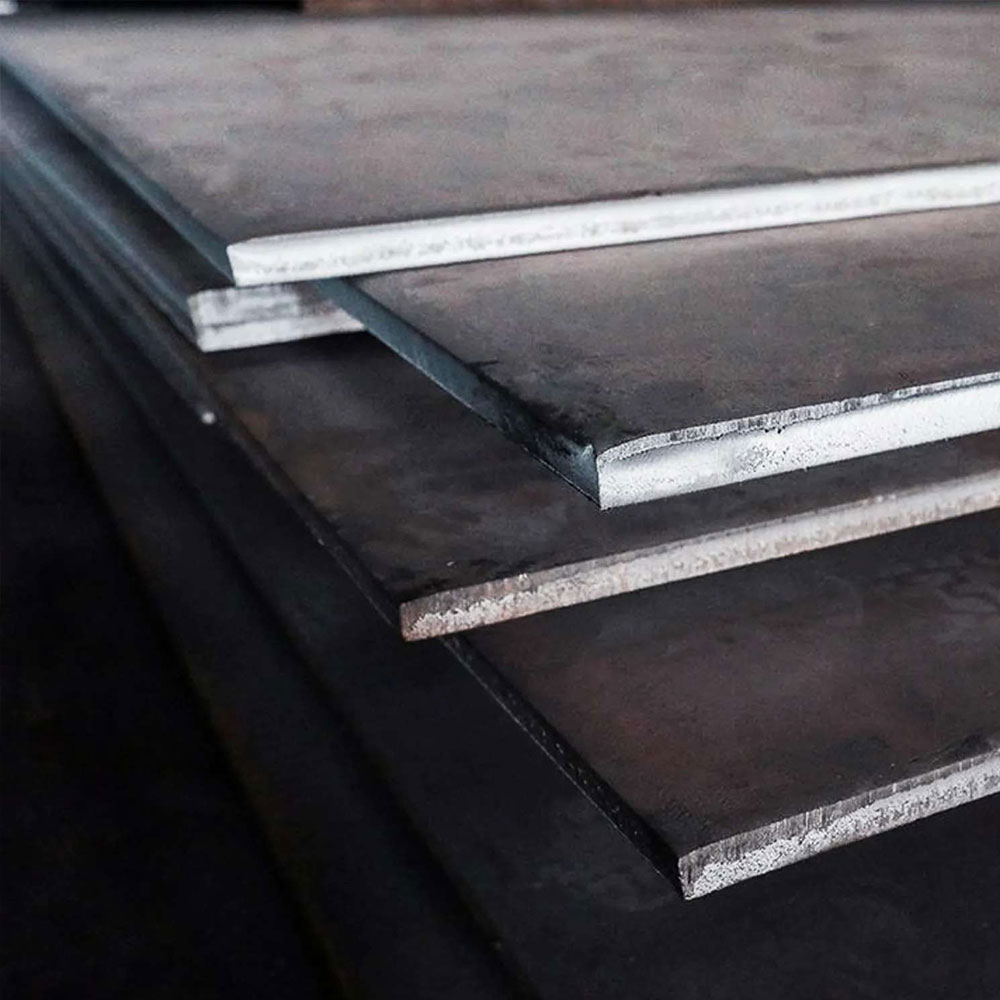

AR400, AR500, NM400/NM500, Boron, and more — built to combat abrasion in mining, cement, and handling systems.

X120Mn12 / ASTM A128 / Hadfield plates for impact resistance in crushers, shot blasters & agricultural tools.

High-strength Q&T plates (S690QL, S890QL, Hiten, Dillimax) for cranes, trailers, and structural uses.

Ballistic steel for military, bunkers, armored cars, and checkpoints – MIL-46100, STANAG, EN1522 compliant.

IBR & PED-ready steel: A516 Gr 60/70, SA387, P265GH for steam boilers, heat exchangers & chemical vessels.

Structural and pressure-use plates like A36, IS 2062, S275, S355, and SS400 in standard and custom cuts.

SAILMA, S355J2, E350, Hiten, Dillimax — high-strength plates for bridges, cranes & heavy fabrication.

Tank-grade and acid-resistant plates for galvanizing, pickling, electroplating & chemical handling.

Plates for bridges, buildings, telecom towers, marine & offshore structures — A36, EN10025, IS2062.

SS 304, 316L, 410, 904L, Duplex — for pharma, marine, dairy & pressure applications.

When your project depends on reliable steel, exact specifications, and time-bound delivery, Hindustan Steel Corporation becomes your single-point solution provider. Whether you’re a buyer, fabricator, or EPC contractor — we don’t just sell plates, we solve problems.

Including HIND HARD (400–600 BHN), HIND MANGANESE, and HIND ARMOR for critical-duty applications

Rockhard, Rockstar, Quard, Abrex, JFE Everhard, Dillimax, Welten, and more — available on-demand.

CNC cutting, beveling, chamfering, and project-specific finishing done in-house.

ISO, IBR, PED, EN, MIL, and STANAG – with 3.1 MTC and Third-Party Inspections (SGS/BV/TUV).

Our steel reaches projects across India, UAE, Saudi Arabia, South Africa, Vietnam, and beyond.

+91-9820944724

At Hindustan Steel Corporation, we specialize in export-ready steel plate solutions tailored for EPC contractors, OEMs, defense suppliers, and global procurement houses. Our team handles end-to-end compliance — from HS codes to packing documentation and third-party inspections.

Export-Centric Support Includes:

No delays. No mismatches. Just tested, traceable, globally compliant steel — from Mumbai to the world.

We don’t just sell steel — we help buyers understand it. Our growing resource hub offers clarity, confidence, and comparison to procurement teams, project engineers, and global buyers evaluating grades, performance, or application suitability.

We’re ready to supply your next project with mill-tested, profile-cut, and globally compliant steel plates — manufactured under the HIND brand or stocked from trusted mills across the world.

WhatsApp us